Alright, let’s talk about Rane Diecast Limited. Maybe you’ve heard the name, maybe you haven’t. Either way, this company plays a pretty significant role in the automotive world, specifically when it comes to those intricate die-cast parts that make your car go. So, what’s the deal with Rane Diecast? Let’s break it down in a way that’s easy to understand.

The Rane Group: A Quick Overview

Before we zoom in on Rane Diecast specifically, it’s helpful to understand where it fits within the bigger picture. Rane Diecast Limited is part of the Rane Group, a well-established conglomerate based in India. The Rane Group is a major player in the automotive components industry, with a history stretching back decades. They’re involved in a wide array of products, from steering systems to engine valves. Think of them as a one-stop shop for many of the parts that keep vehicles running smoothly.

Being part of the Rane Group gives Rane Diecast a strong foundation. It benefits from the group’s established reputation, resources, and expertise. This also means they have access to a broader network of customers and suppliers, which is crucial in the competitive automotive market.

So, What Exactly Does Rane Diecast Do?

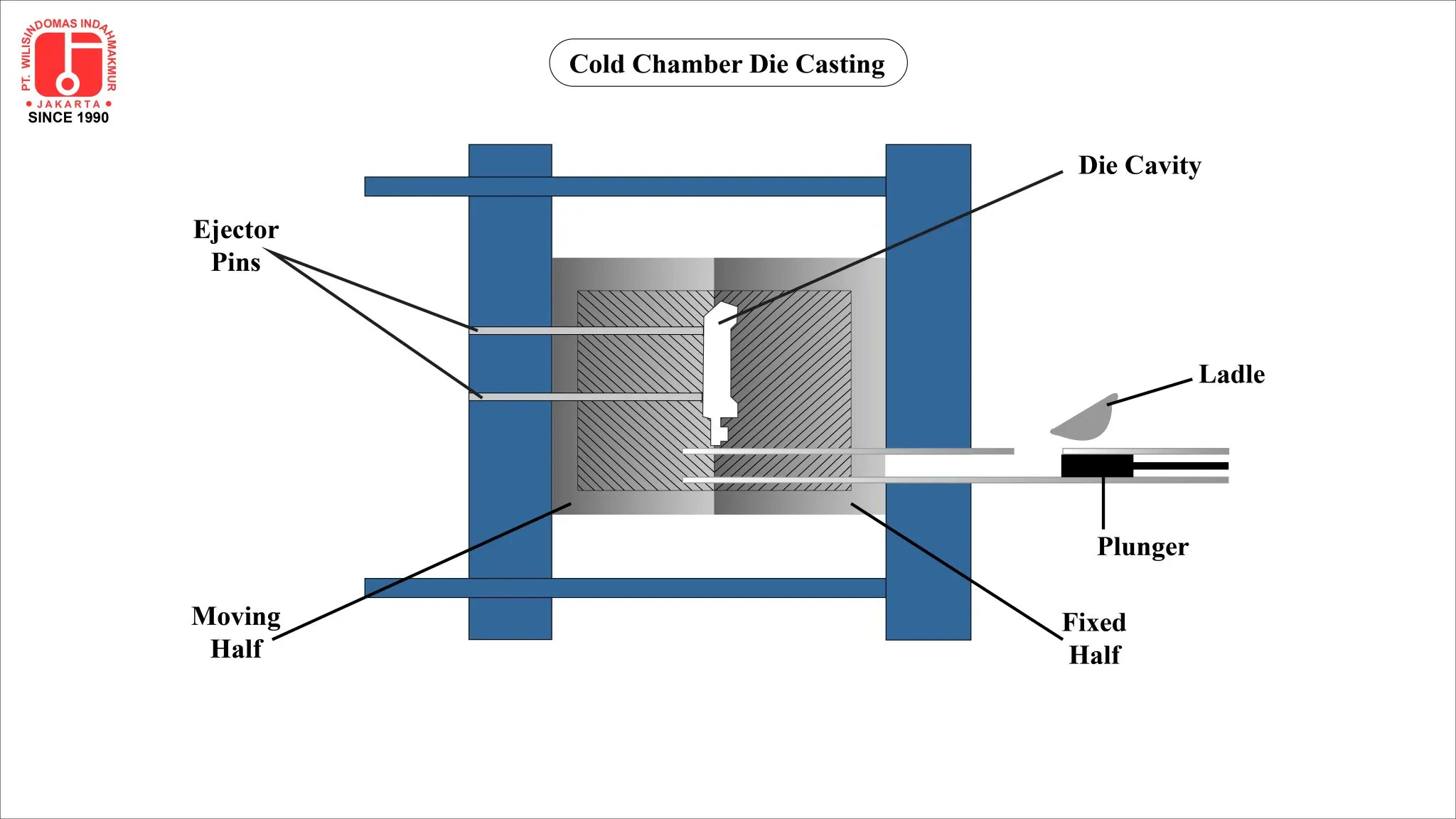

Now, let’s get down to the nitty-gritty. Rane Diecast Limited specializes in, you guessed it, die casting. But what does that actually mean? Die casting is a manufacturing process where molten metal is injected under high pressure into a mold cavity. This mold, or die, is typically made from steel and is carefully designed to create a specific part shape. Once the metal cools and solidifies, the die is opened, and the finished part is ejected.

Think of it like making a metal version of a plastic toy using a mold, only on a much larger and more precise scale. The die casting process is known for its ability to produce complex shapes with high accuracy and repeatability. This makes it ideal for manufacturing automotive components that require tight tolerances and consistent quality.

Rane Diecast produces a variety of die-cast components, typically from aluminum or zinc alloys. These components find their way into various automotive applications, including engine parts, transmission components, and steering systems. They work with a wide range of automakers and automotive suppliers, providing them with the parts they need to build vehicles.

Products and Applications

Rane Diecast’s product portfolio is quite diverse, catering to different automotive needs. Some of their key product areas include:

- Engine Components: Parts like cylinder heads, engine blocks, and oil pans.

- Transmission Components: Housings, valve bodies, and other critical parts that make your car shift smoothly.

- Steering System Components: Components used in power steering systems and other steering mechanisms.

- Other Automotive Parts: Various other die-cast parts used in different vehicle systems.

These parts are crucial for the performance, reliability, and safety of vehicles. Rane Diecast focuses on producing high-quality components that meet the stringent requirements of the automotive industry. This involves using advanced manufacturing techniques, rigorous quality control processes, and continuous improvement efforts.

Manufacturing Capabilities and Technology

To produce these intricate die-cast parts, Rane Diecast invests heavily in its manufacturing facilities and technology. They utilize state-of-the-art die casting machines, robotic automation, and advanced quality control equipment. This allows them to achieve high levels of precision, efficiency, and consistency in their production processes.

They also employ a team of skilled engineers, technicians, and operators who are experts in die casting and related technologies. These professionals play a vital role in ensuring the quality and reliability of Rane Diecast’s products. Continuous training and development programs help them stay up-to-date with the latest advancements in the industry.

Furthermore, Rane Diecast emphasizes research and development to explore new materials, processes, and designs. This allows them to offer innovative solutions to their customers and stay ahead of the competition. They work closely with automakers and other industry partners to develop custom die-cast components that meet their specific needs.

Quality and Certifications

In the automotive industry, quality is paramount. Rane Diecast understands this and places a strong emphasis on quality control throughout its operations. They implement rigorous quality management systems to ensure that their products meet the highest standards of performance and reliability.

Rane Diecast has obtained various certifications, such as ISO 9001 and IATF 16949, which demonstrate their commitment to quality and continuous improvement. These certifications are recognized globally and are essential for suppliers in the automotive industry. They require companies to implement robust quality management systems, conduct regular audits, and continuously improve their processes.

Their dedication to quality extends beyond certifications. They employ advanced testing equipment and techniques to verify the performance and durability of their die-cast components. This includes dimensional measurements, material analysis, and performance testing under various conditions.

Rane Diecast in 2024 and Beyond

Looking ahead to 2024 and beyond, Rane Diecast is well-positioned to continue its growth and success in the automotive industry. The demand for lightweight and high-performance automotive components is increasing, driven by factors such as fuel efficiency regulations and the rise of electric vehicles. Die casting is an ideal manufacturing process for producing these types of components.

Rane Diecast is also actively exploring opportunities in emerging markets and new applications for its die-cast products. This includes expanding its customer base, developing new product lines, and investing in advanced technologies. They are committed to providing their customers with innovative and cost-effective solutions that meet their evolving needs.

Furthermore, Rane Diecast recognizes the importance of sustainability and is taking steps to reduce its environmental impact. They are implementing energy-efficient manufacturing processes, using recycled materials, and reducing waste. This aligns with the growing trend towards sustainable manufacturing in the automotive industry.

Why Rane Diecast Matters

So, why should you care about Rane Diecast? Well, they’re a crucial link in the automotive supply chain. They produce the parts that automakers rely on to build reliable and efficient vehicles. Without companies like Rane Diecast, the cars we drive wouldn’t be possible. They’re a quiet force, working behind the scenes to keep the automotive industry moving forward.

Their commitment to quality, innovation, and sustainability makes them a valuable partner for automakers and other industry players. They’re constantly striving to improve their processes, develop new products, and reduce their environmental impact. This makes them a company to watch in the years to come.

In conclusion, Rane Diecast Limited is a significant player in the die-casting industry, providing critical components to the automotive sector. Their dedication to quality, technological advancement, and sustainable practices ensures their continued relevance and contribution to the evolving landscape of automotive manufacturing. Hopefully, this gives you a better understanding of who Rane Diecast is and what they do.