It’s amazing to hold a miniature replica of your favorite car, perfectly scaled down to the last detail. But have you ever stopped to think about the journey that tiny car takes, from a blob of metal to a collector’s item?

The creation of a diecast model car is a fascinating process, involving many intricate steps and specialized machinery. Let’s explore the world of diecast model car factories and uncover the secrets behind these miniature marvels.

The Beginning: Designing the Masterpiece

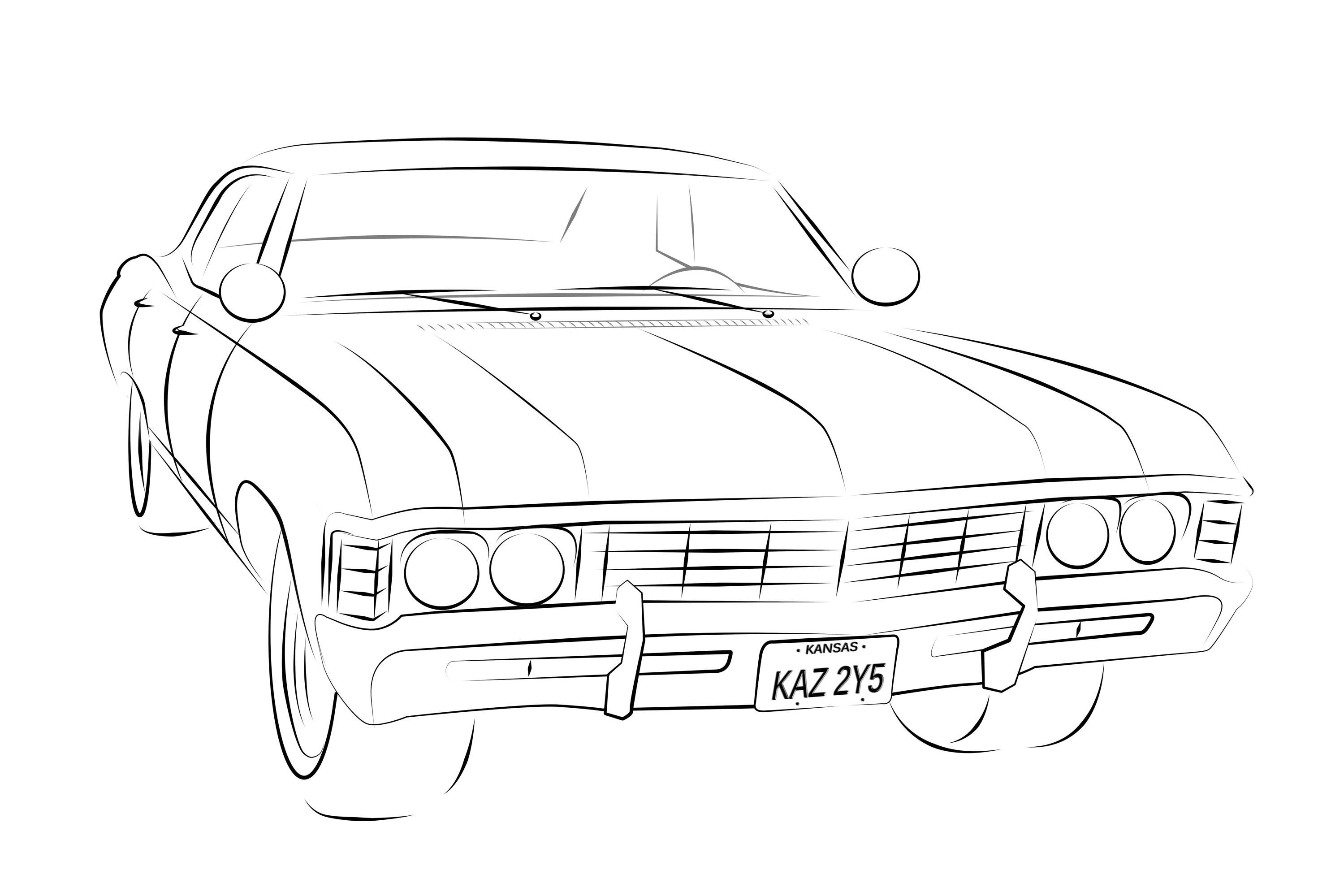

Before any metal is even touched, the design process is key. Designers work closely with the original car manufacturers (or create their own original designs) to ensure incredible accuracy. This involves creating detailed blueprints and 3D models, capturing every curve, line, and detail of the full-size vehicle.

Once the design is finalized and approved, the next stage involves creating a master tooling. This is a complex, highly precise mold that will be used to shape the countless miniature car bodies.

The Metalworking Magic: Casting and Shaping

With the master tooling ready, the factory’s powerful machines take over. Molten metal, typically zinc alloy or sometimes even more specialized metals, is injected into the mold under high pressure. This process is known as die casting. The metal quickly solidifies, taking the shape of the mold.

Once cooled, the diecast car body is carefully ejected from the mold. This process is repeated thousands, even millions, of times to create a steady stream of car bodies. This might seem simplistic, but the precision involved is incredible; a slight imperfection in the mold can ruin many diecast cars.

Adding the Details: Painting and Assembly

Now, the raw diecast car body is far from finished. It’s time for the detail work. The bodies undergo a thorough cleaning process, prepping them for the next step: painting. Robotic arms, or sometimes skilled human hands, meticulously apply layers of paint to match the real car’s color scheme.

After the paint dries, the assembly begins. Tiny wheels, windows, lights, and other parts are attached, often using automated assembly lines. Some manufacturers even add incredibly detailed interiors. The level of detail is really quite remarkable for such a small-scale item.

Quality Control: Ensuring Perfection

Throughout the entire process, quality control plays a vital role. Inspectors carefully examine the diecast models for any defects, ensuring that only the highest quality products leave the factory. These checkpoints are crucial to maintaining a brand’s reputation.

Packaging and Distribution: Ready for Collectors

Once the diecast models pass inspection, they’re packaged. This involves placing them in protective boxes, sometimes including additional features like collector’s cards or display bases. These are then shipped to distributors and retailers around the world, ready to be enjoyed by enthusiasts and collectors.

So, next time you admire a diecast model car, remember the incredible journey it’s taken, from a design on paper to a meticulously crafted piece in your hands. It’s a testament to engineering, artistry, and a passion for detail.

- Design and tooling creation

- Die casting of the metal body

- Cleaning and surface preparation

- Painting and finishing

- Assembly of parts

- Quality control inspection

- Packaging and distribution