So you’ve got a shiny new diecast model car. But did you ever think about the journey that tiny metal blank took to get to its finished state? It’s a surprisingly intricate process, involving many steps and a lot of expertise. Let’s explore the fascinating world of diecast finishing!

The Beginning: Preparing the Diecast

Before any paint or polish touches the diecast, it needs a thorough cleaning. Think of it as a car wash for tiny cars! This removes any oils, grease, or other contaminants left over from the casting process. This is crucial for ensuring the paint adheres properly and prevents defects.

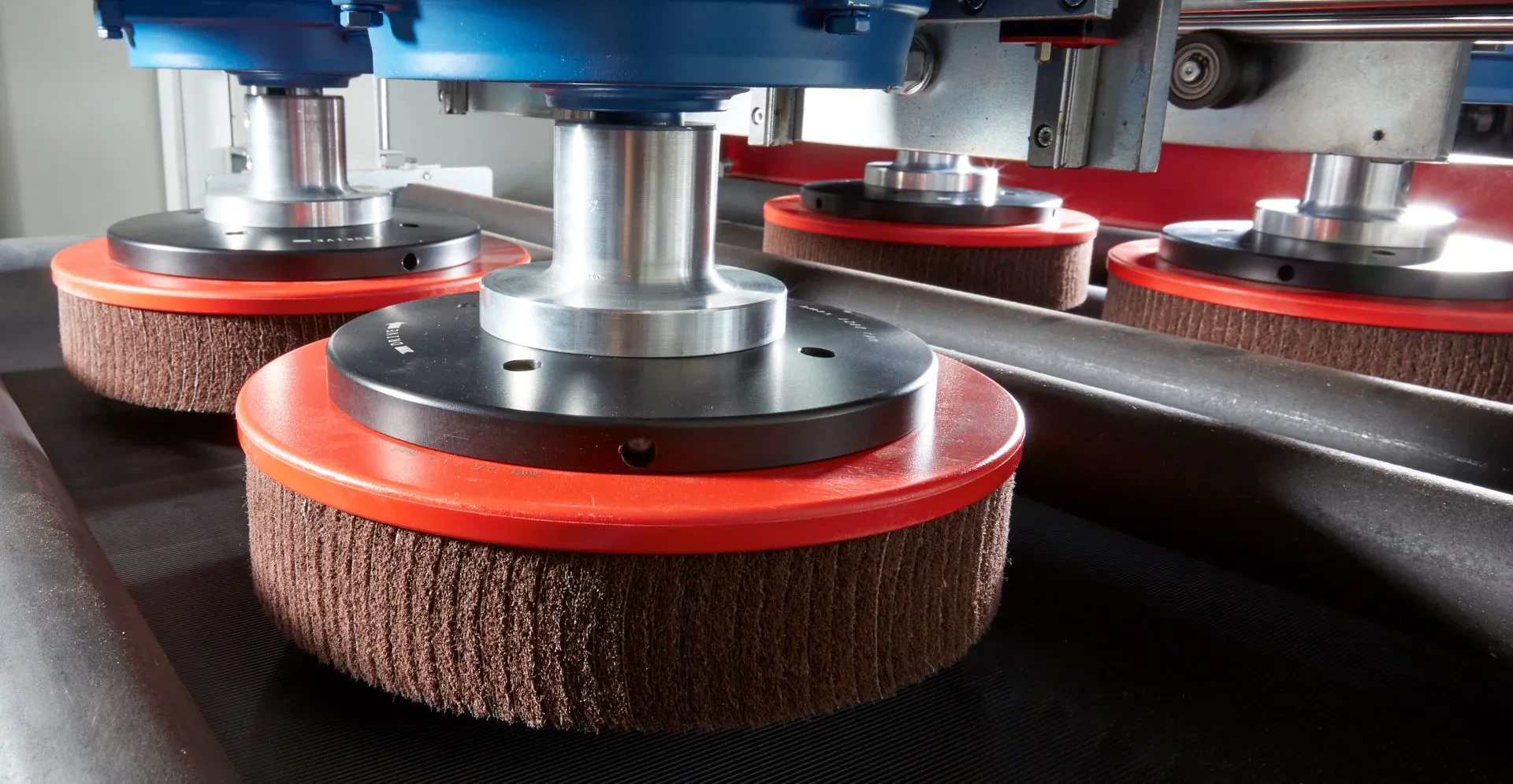

After cleaning, the diecast often undergoes a process called deburring. Tiny bits of excess metal, called burrs, can be left over from the casting process. These need to be carefully removed to create a smooth surface for painting. This is usually done using automated machinery for efficiency and consistency.

Priming: The Foundation for Perfection

Next comes priming. This is like applying a base coat to a wall before painting. A primer helps the paint adhere better and provides a uniform surface. Different primers are used depending on the type of paint and the desired finish.

Painting: Adding Color and Detail

This is where the magic happens! The diecast is carefully painted, often using automated spray systems to ensure consistent coverage. Multiple layers of paint may be applied, with drying time in between. For complex designs and intricate details, masking techniques are used to protect certain areas from being painted.

Different paint types are used, such as acrylics, lacquers, or enamels, each offering unique properties in terms of durability, shine, and application.

Adding Details: Tampo Printing and More

Once the base color is applied, details like logos, stripes, and numbers are often added using a process called tampo printing. This involves using a special pad to transfer ink onto the diecast, allowing for intricate designs.

Other details like decals or even small, separate parts may be added at this stage.

Finishing Touches: Polishing and Clear Coating

After painting and detailing, the diecast may undergo polishing to achieve a smooth, glossy finish. This helps to highlight the details and enhance the overall appearance. A clear coat is often applied on top to protect the paint and add extra shine. This layer also contributes to the model’s overall durability and resistance to scratches.

Quality Control: Ensuring Perfection

Throughout the entire process, quality control checks are carried out to ensure that each diecast meets the highest standards. Defective pieces are rejected, and any necessary corrections are made.

Plating: A Shiny Upgrade

For a truly luxurious finish, some diecast models undergo plating. This involves coating the diecast with a thin layer of metal, such as chrome, gold, or nickel, giving it a brilliant and highly reflective surface.

- Cleaning

- Deburring

- Priming

- Painting

- Tampo Printing/Decaling

- Polishing

- Clear Coating

- Plating (Optional)

- Quality Control

And there you have it! From a simple metal blank to a stunning, highly detailed diecast model, the journey involves many steps of precision and artistry. Next time you admire your collection, remember the incredible process behind each tiny masterpiece.