Okay, let’s be real. When you first hear about someone turning a diecast car into a guitar pedal, your first thought might be, “That’s… different.” But trust me, once you understand the appeal and see the ingenuity, you’ll be hooked. The world of DIY guitar pedals is already pretty wild, but adding diecast cars to the mix? That’s next-level awesome.

Why Diecast Cars? The Appeal of Automotive Tone

So, why go through the effort of stuffing a circuit board into a miniature car? Several reasons, actually. First, aesthetics. A diecast car pedal is undeniably cool. It’s a conversation starter, a visual statement, and a way to personalize your rig in a way that a standard metal enclosure just can’t match.

Second, the challenge. For DIY enthusiasts, building a diecast car pedal is a fun and unique project. It requires creativity, problem-solving skills, and a willingness to experiment. It’s not just about soldering components; it’s about figuring out how to cram everything into a tight space and make it look good.

Third, the novelty. Let’s face it, it’s just plain fun to stomp on a miniature DeLorean to activate your overdrive. It’s a way to inject some humor and personality into your playing, and that’s always a good thing.

The Basics: What You’ll Need

Alright, so you’re intrigued. What do you need to get started? Here’s a breakdown of the essential components:

- A diecast car: Choose one with enough internal space and a suitable aesthetic. Larger cars, like vans or trucks, are generally easier to work with.

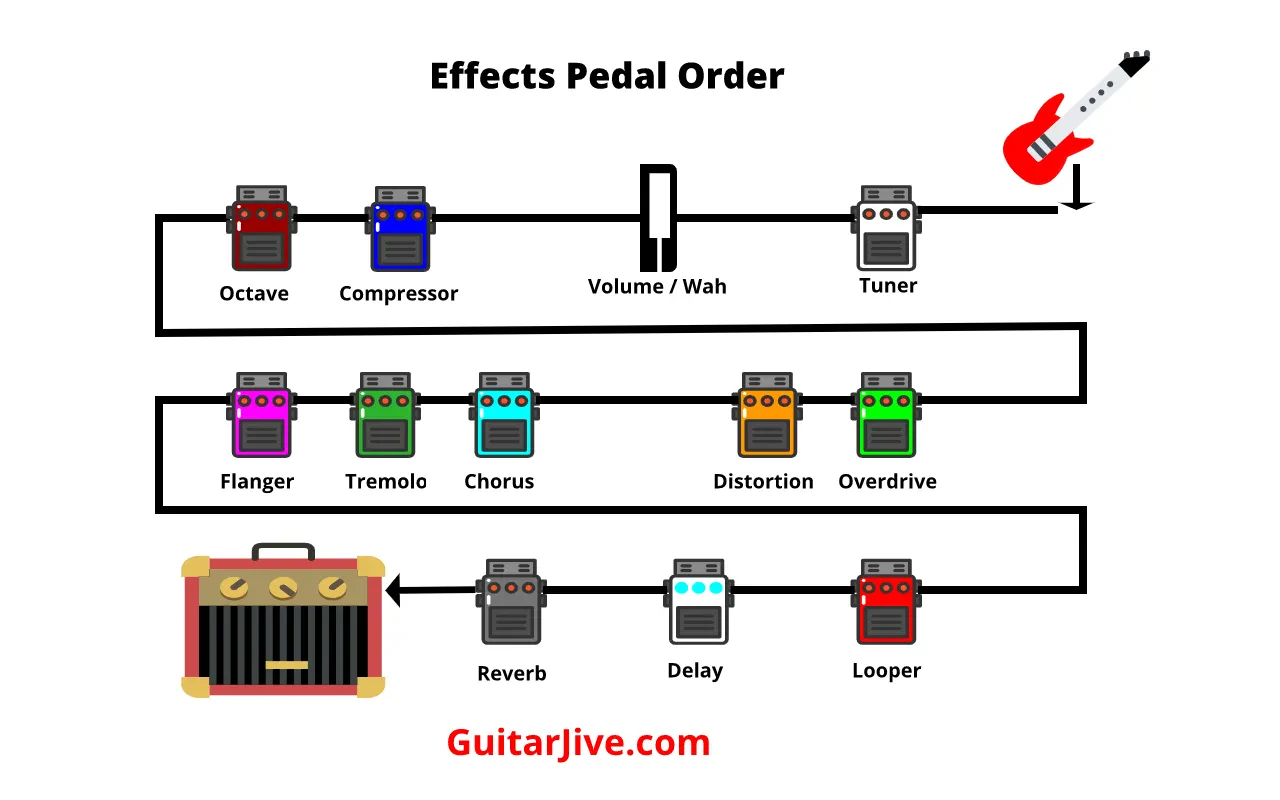

- A guitar pedal circuit: This could be a kit, a pre-built board, or a circuit you’ve designed yourself. Overdrive, distortion, fuzz, and boost circuits are popular choices.

- 3PDT footswitch: This is the switch that turns the effect on and off.

- Input and output jacks: Standard 1/4" jacks for connecting your guitar and amp.

- DC power jack: For powering the pedal with a standard 9V power supply.

- Potentiometers: These are the knobs that control the various parameters of the effect, like gain, tone, and volume.

- Wiring: To connect all the components together.

- Tools: Soldering iron, solder, wire strippers, pliers, drill, rotary tool (like a Dremel), and various screwdrivers.

The Build Process: From Toy Car to Tone Machine

Now for the fun part: actually building the pedal. Here’s a step-by-step guide:

Step 1: Disassembly. Carefully take apart the diecast car. You’ll likely need to remove screws or rivets. Be gentle to avoid damaging the car’s body.

Step 2: Gutting. Remove the interior of the car, leaving only the outer shell. You may need to cut away plastic or metal to create enough space for the circuit board and other components.

Step 3: Drilling. Drill holes for the footswitch, input/output jacks, DC power jack, and potentiometers. Precise placement is crucial, so measure carefully.

Step 4: Mounting Components. Securely mount the footswitch, jacks, and potentiometers to the car’s body. This may involve using nuts, bolts, or epoxy.

Step 5: Wiring. Wire up the circuit according to the schematic. This is where your soldering skills come into play. Be neat and organized to avoid shorts and other problems.

Step 6: Testing. Before permanently securing everything, test the circuit to make sure it’s working correctly. Use a multimeter to check for shorts and proper voltage readings.

Step 7: Assembly. Once you’re confident that everything is working, carefully reassemble the car. Make sure all the components are securely mounted and that the wiring is tidy.

Challenges and Considerations

Building a diecast car pedal isn’t always easy. Here are some common challenges and things to keep in mind:

Space constraints: Fitting all the components into a small diecast car can be tricky. Choose a circuit that’s compact and well-suited for tight spaces. Consider using smaller components, like surface-mount resistors and capacitors.

Heat dissipation: Guitar pedal circuits can generate heat, especially high-gain circuits. Make sure there’s adequate ventilation to prevent overheating. Consider using a heat sink to dissipate heat away from critical components.

Durability: Diecast cars aren’t designed to be stomped on repeatedly. Reinforce the car’s body with epoxy or metal bracing to prevent it from cracking or breaking. Be mindful of the footswitch placement, as it will be subjected to the most stress.

Aesthetics: While the novelty is cool, think about usability. Where are the knobs placed, and how easy is it to adjust them while playing? How will the graphics look after a few stomps?

Grounding: Proper grounding is essential to prevent noise and hum. Make sure all the components are properly grounded to the car’s body. Consider using shielded cable for sensitive signal paths.

Creative Ideas and Customizations

Once you’ve mastered the basics, you can start getting creative with your diecast car pedals. Here are some ideas to inspire you:

Themed builds: Choose a car and a circuit that complement each other thematically. For example, a DeLorean with a delay circuit, or a police car with a tremolo effect.

Hidden controls: Integrate the potentiometers into the car’s design. For example, use the car’s headlights as knobs, or hide the controls under the hood.

Lighting effects: Add LEDs to the car to create cool lighting effects. You could use LEDs that pulse with the tempo of the music, or LEDs that change color based on the pedal’s settings.

Multiple effects: Build a pedal with multiple effects housed in a larger diecast vehicle, like a van or truck.

Custom paint jobs: Give your diecast car a custom paint job to match your personal style.

Where to Find Inspiration and Resources

Need some inspiration? Here are some places to look:

- Online forums: Check out guitar pedal building forums for ideas, tips, and troubleshooting advice.

- YouTube: Search for “diecast car pedal build” to find tutorials and demonstrations.

- Instagram: Follow hashtags like #diecastpedal, #guitarpedals, and #diyguitar to see what other builders are creating.

- Etsy and Reverb: Browse online marketplaces to see if anyone is selling pre-made diecast car pedals.

So, there you have it. A crash course in the weird and wonderful world of diecast car guitar pedals. It’s a challenging but rewarding project that allows you to combine your love of music with your passion for collecting and creating. So grab a diecast car, a soldering iron, and get ready to rock!

Remember to always prioritize safety when working with electronics and power tools. If you’re not comfortable with any aspect of the build process, seek help from a qualified technician.

Happy building in 2024, and may your tone be forever automotive!